Main features

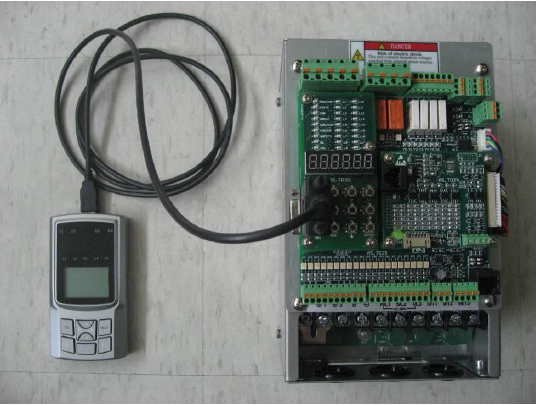

a) Prefect integration of control and drive of elevator. The whole device features compact

structure and small size, fewer connections, which is characterized as high reliability and

easy-to-use property and cost-efficiency.

b) Double 32-bit embedded microprocessor jointly finish the elevator operation and motor drive control.

c) Redundant safety design , double safety protection for control processor and drive processor to achieve the maximum safety guarantee for elevator travel.

d) The design requirements of anti-interference capacity go beyond the highest standard in the

industrial design requirement.

e) All CAN bus communication make the whole system connected easily, data transmitted

strongly, and more reliable.

f) The adoption of the advanced direct landing technology make elevator running efficiently.

g) The advanced multifunctional elevator operation mode can fully meet various needs of

customers’.

h) Advanced group control feature. Not only compatible with the traditional group control mode of up to 8 units, but also support the new group control of destination floor distribution.

i) The adoption of advanced vector control technology can make the motor speed adjusted well.

for the realization of the best elevator comfort.

j) Adapt to both synchronous motor and asynchronous motor.

k) Newly-developed none-load sensor-activated compensation technology provides excellent

starting comfort to elevator even if no counterweight is installed.

l) To adopt incremental ABZ encoder to realize the synchronized control of motors. To adopt the none-load sensor-activated compensation technology to achieve the excellent start-up comfort.

m) New PWM dead band compensation technology can effectively reduce the motor noise and loss of machine.

n) Dynamic PWM carrier modulation technology can effectively reduce the motor noise.

o) Auto-tuning phase of synchronous motor without encoder.

p) Asynchronous motor is not required for motor parameter acquisition process once the motor. parameter is set correctly. The convenient static motor parameter acquisition process is available If is impossible to acquire the exact motor parameter on site. So there is no need to hoist the car and etc in this way.

q) The hardware is the 6th generation of module with the junction temperature resistance up to

175℃. Low loss for switch and connection to ensure the long use life.